A Mr. Rooter plumbing technician will locate the sewer line exiting the home, then locate the cleanout closest to your property. If a cleanout is not available, we will install one. This should be a two-way cleanout, allowing for the necessary access to the city mainline and the old, decaying sewer pipe under the home. In most communities, a two-way cleanout is a plumbing code standard. Establishing this access will occur the day prior to the cleaning and coating procedure.

Sewer Line Repair Services

Damaged sewer pipes can be more than just a costly repair—they can result in extensive and expensive property damage and lead to serious health risks. Sewer line repair is the first line of defense when a sewer line fails. If the sewer line can’t be repaired, sewer line replacement is the only other option.

Fortunately, Mr. Rooter® Plumbing is your local source for quality sewer repair and replacement at any time. Below, we explain some causes of sewer line damage, tips that can help you identify the problem, and the services we provide to give you solutions.

Are you dealing with heavily scaled and decaying cast iron sewer lines that need replacement?

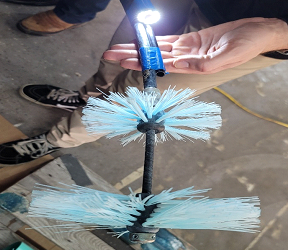

Mr. Rooter® Plumbing uses the best sewer coating and lining equipment in the industry. For example, Picote Solutions provides a method of safely and efficiently de-scaling and epoxy-coating cast iron sewer lines. These millers provide:

- High RPM drain cleaning including soft blockages

- Calcium & sewage scale build-up

- Concrete & lead deposits

- Tree roots

Our highly trained technicians will clean and descale the existing pipes, then apply a seamless epoxy coating, allowing for proper sewage flow away from your property while significantly extending the life of the sewer system.

Our Process

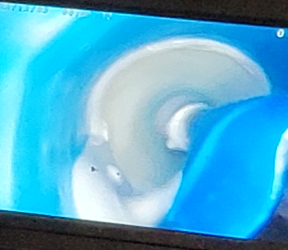

Once the official process begins, the water to the home cannot be turned off, and none of the plumbing fixtures within the home may be used. Using the external cleanout established the day prior, our technicians will access the sewer pipe to be coated, camera the line(s) in question, and establish a process plan. All of the pipes to be coated will be thoroughly cleaned and then hydroscrubbed to remove all scale, roots, and other deposits existing within that portion of the sewer system. This process may take as long as the whole day.

While the pipes are drying, our technicians will begin preparations to apply the coatings.

The line(s) to be re-coated will be inspected again to ensure they are clean and dry. Using high-speed milling equipment, epoxy coating is pumped into the pipes to apply the epoxy resin. We use an inspection camera to ensure the coating is applied thoroughly to the pipe.

This process is repeated a second time. Once the epoxy resin is properly cured, a final camera inspection of the completed process will be checked to ensure all internal surfaces of the pipe are properly coated.

Benefits of Pipe Brush Coating Repair

Pipe brush coating is a minimally invasive process that allows the rehabilitation of existing drainage pipe(s) without having to tear them out and replace them conventionally. In short, the result is a brand-new pipe within the old pipe with a 10 to 15-year life expectancy.

In most cases, sewer pipe coating costs are 30-40% less expensive than conventional demolition and replacement repair methods. The pipe coating process is less intrusive and faster than conventional repair methods.

Signs of a Broken Sewer Pipe:

- Strange gurgling noises coming from your toilet(s)

- Lack of water in your toilet(s)

- Slow draining bathtub/failure to drain

- Noticeable sewage backup in your toilet or tub

- Sewer odor in your basement, yard, or other areas of your property

- Significantly greener grass near your sewage pipe

- Flooded yard